FREE EXPEDITED SHIPPING ON ALL DOMESTIC LEATHER BELT ORDERS

FREE EXPEDITED SHIPPING ON ALL DOMESTIC LEATHER BELT ORDERS

Belts

About

The Art of Crafting a Bespoke Leather Belt: A Step-by-Step Guide from Design to Production

February 15, 2023 4 min read

When it comes to accessories, few items are as timeless and classic as a leather belt. Whether you're looking for a casual, everyday belt or something more formal for special occasions, a well-made leather belt is an essential part of any wardrobe. For those who want the ultimate in quality and customization, a bespoke leather belt is the way to go.

But what exactly goes into the process of creating a bespoke leather belt? From the initial design to the final production, there are many steps involved in crafting a belt that is truly one-of-a-kind. In this article, we'll take a closer look at the art of creating a bespoke leather belt, from start to finish.

Step 1: Designing Your Belt

The first step in creating a bespoke leather belt is to design the look. This is where you'll decide on everything from the type of leather to the buckle style and color. Depending on the company you're working with, you may have the option to design your belt entirely from scratch or choose from a selection of pre-designed templates and customize them to your liking.

If you're starting from scratch, it's a good idea to have a clear idea of what you want your belt to look like before you start designing. Consider factors such as the occasion you'll be wearing your belt, your personal style, and the colors and patterns you like. You may also want to consider the color and style of your shoes and other accessories to ensure that your belt complements your overall look. For instance, if you have a special event, Roger Ximenez dress belts may be a great option.

Once you have a clear idea of what you want your belt to look like, you can begin the design process. This may involve working with a designer or using a design tool to create a visual representation of your belt. Be sure to consider all the details, such as the width of the belt, the type of buckle, and any additional features you may want, such as stitching color or embossing.

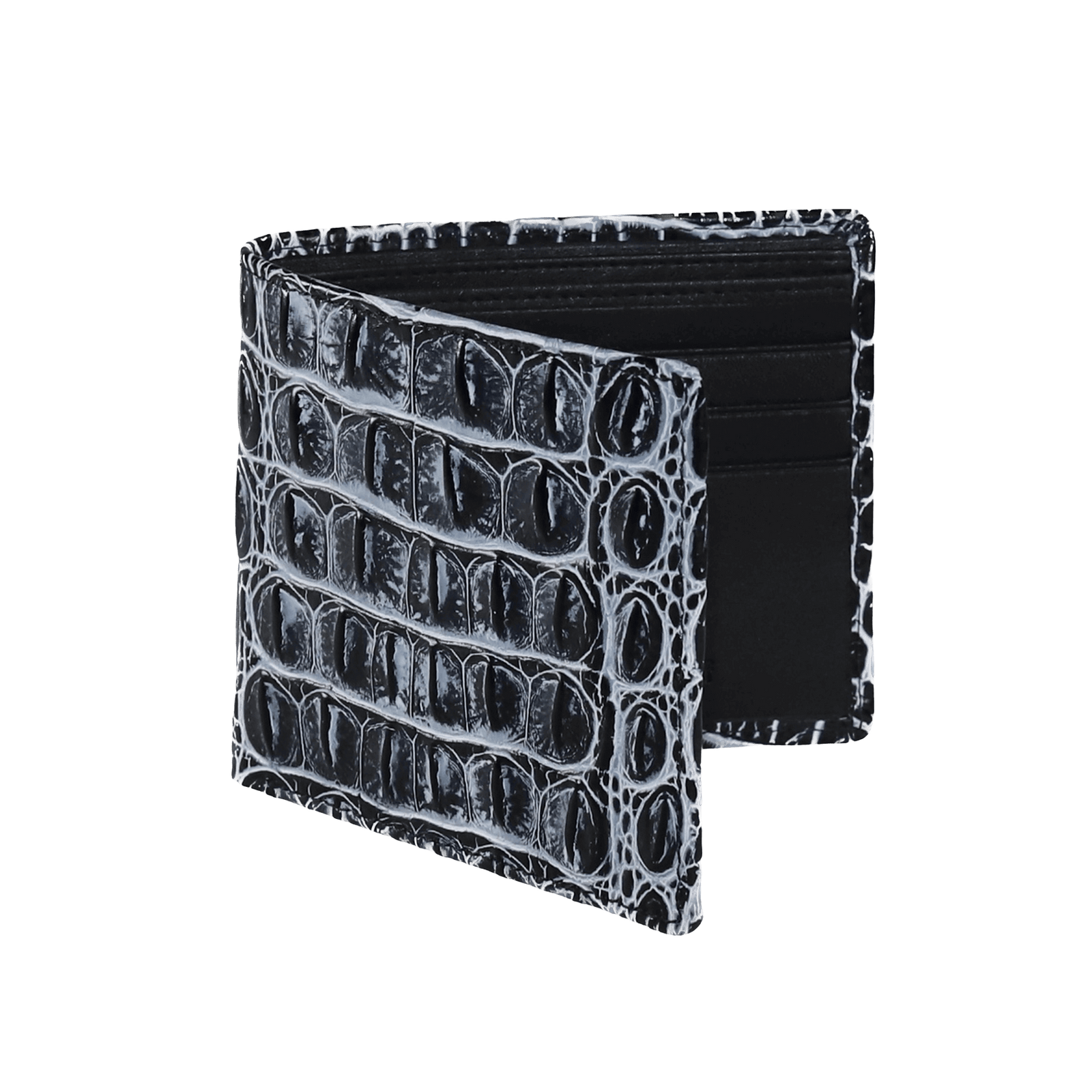

Step 2: Choosing Your Leather

Once you have a design in mind, the next step is to choose the type of leather you want to use for your belt. There are many different types of leather to choose from, each with its own unique characteristics. Some common types of leather used for belts include cowhide, suede, calfskin, and exotics like alligator or snake. At Roger Ximenez, you'll find a large collection of calf skins in smooth or embossed patterns, suede and exotic leathers to choose from. You will also find some premium leather styles such as Italian Pebble Grain or Mock Croc.

When choosing your leather, consider factors such as the desired look and feel of your belt, the level of durability you need, and any specific needs you may have (such as allergies to certain types of leather). Be sure to also consider the color and finish of the leather, as this can have a significant impact on the overall appearance of your belt.

Step 3: Cutting and Preparing the Leather

Once you have chosen your leather, the next step is to cut it to the appropriate size and shape. This is typically done using a leather cutting machine, which uses a sharp blade to cut the leather to the desired size and shape. The leather is then sanded or buffed multiple times to remove any rough edges and prepared for the next step in the process.

Step 4: Adding Stitching and Embellishments

After the leather has been cut and prepared, the next step is to add any stitching or embellishments that you have chosen for your belt. This may include decorative stitching, embossing, or other decorative elements. This is typically done by hand, using specialized tools and techniques.

Step 5: Attaching the Buckle

Once the leather has been stitched and embellished, the next step is to attach the buckle. This is typically done using a strong adhesive and may require the use of specialized tools to ensure a secure connection. Roger Ximenez belts are designed with a unique screw system that allows customers to remove the buckle, cut the belt to a new size and reattach with ease.

Step 6: Finishing and Polishing

Once the buckle has been attached, the final step in the production process is to finish and polish the belt. This typically involves applying a protective coating to the leather to help preserve its color and shine. It may also involve buffing or polishing the leather to give it a smooth, polished finish.

Step 7: Quality Control and Shipping

Before a belt is shipped out to the customer, it undergoes a thorough quality control process to ensure that it meets the highest standards of craftsmanship. This may include inspections for defects, wear, and other issues that could affect the quality of the belt. Once the belt has passed the quality control process, it is carefully packaged and shipped out to the customer.

The process of creating a bespoke leather belt is a true art form, requiring a combination of skill, attention to detail, and a passion for craftsmanship. From the initial design to the final production, each step is carefully considered to ensure that the end result is a one-of-a-kind belt that is made to last. Whether you're looking for a casual, everyday belt or something more formal for special occasions, a bespoke leather belt is a timeless accessory that will add a touch of sophistication to any outfit.

Subscribe

Sign up to get the latest on sales, new releases and more …